|

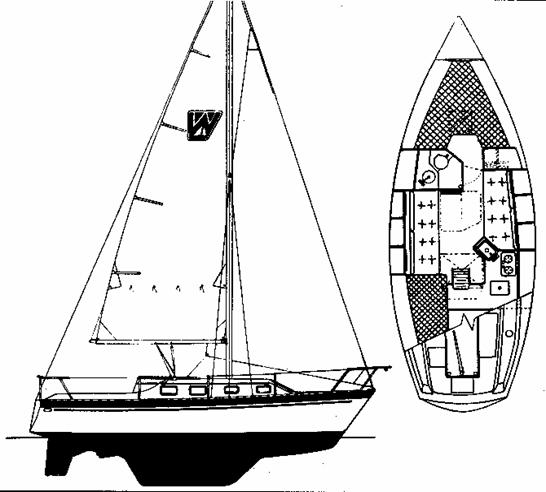

W A T K I N S W 2 9 / W 3 0 |

|

D E S I G N & H I S T O R Y The W29 was first introduced in 1984. In 1988 the rear transom was slightly changed from nearly vertical to a reverse style and the model designator changed to W30. The W30 model continued in production until the factory closed. The last known Watkins boat to be built by the factory was a W30 whose hull was molded in April of 1989 as a 1990 model. Total production of the W29 & W30 was 88 boats. At least 60 of the total were W29s leaving less than 28 which could be W30s.

The boat is sloop rigged with a 4 draft and a skeg mounted rudder. Her interior offers accommodations for five including a quarter berth with the option of a pull out double berth to port. Standard items includes diesel engine, pressure water, shower, eight opening ports, bulkhead mounted dining table and shore power. The galley is to starboard with a sink, stove, icebox and storage. There is a hanging locker opposite of the head forward. Headroom is 63 and her mast height above DWL is 401. |

|

Specifications LOA . ..2811 LWL . . ...240 Beam . ..104 Draft . .. .40 Disp. ....8,800 lbs. Ballast .3,900 lbs. Sail Area .385 sq. ft. Fuel ...20 gal. Water .40 gal. DWL .....401 Designer ..Watkins |

H U L L & D E C KThe hull is molded as a single unit of a combination of polyester resin and fiberglass woven roving and multidirectional chopped strand fiber (MCSF). The keel is molded integrally with the hull and all ballast is contained inside. The deck and cockpit, like the hull, are molded as a single unit of a combination of polyester resin and fiberglass woven roving and MCSF. Plywood coring is incorporated between layers of fiberglass in the cabin top, deck, seat, and cockpit sole areas to give additional stiffness. The non-skid finish is molded into the deck. The exterior finish is pigmented gelcoat molded onto the fiberglass. The boot and sheer stripe are also gelcoat molded permanently into the hull. R U D D E R & S T E E R I N GThe rudder is molded as a single piece of solid high density foam with a protective skin of fiberglass and a gelcoat finish. The rudder post, molded integrally with the rudder, is solid stainless steel, which is welded to a steel blade in the interior of the rudder. S P A R S & R I G G I N GAll spars (mast, boom, and spreaders) are extruded aluminum 6061-T6 alloy, with a protective coating an all external surfaces. The masts has a single spreader, and booms with single reefing. The main sheet traveler is mounted on the cabin top. I N T E R I O RThe interior is a molded fiberglass unit with bulkheads and cabinetry fastened to it with screws, bolts, and adhesives. The interior molded assembly is bonded to the hull with woven roving and mat, that when completed, forms a single unit structure having great strength and rigidity. A U X I L A R YYanmar diesel engines were standard equipment. The 2GM20 (18hp) and 3GM30 (27hp) engines were used. The propeller shaft is made of 1" stainless steel and exits the hull through a stuffing box. It is supported at the inboard, or engine end, by the shaft coupling, and at the aft end by a cutless bearing in a shaft log that is a continuation of the keel. In Yanmar engines, the water pump draws water through the engine intake port, circulates it through the engine block, and then into the muffler. The water is mixed with the exhaust gases in the muffler and discharged overboard through the exhaust port. E L E C T R I C A L . .S Y S T E MThe standard battery configuration consisted of two 12-volt batteries connected in parallel to allow single or combined use and charged from the stock 35 amp Hitachi alternator.

|