HOME HISTORY OF WATKINS YACHTS

|

|

Last Address: Watkins Yachts Inc. Div of McLaughlin Body Co. 12645-49th Street North, Clearwater, Fl. 33520 Boat Production The Watkins Company built slightly more than 1,280 sailboats and over 210 power boats between August 1973 and November of 1989. The photo at right was taken in 1988 of the front of the factory. Additional photos are at the end of this article. |

The Watkins Yacht and Marine Company was founded by four Watkins brothers for the purpose of building sailboats. The brothers divided up the management of the company as follows: Redford—Advertising; Richard—Production; Robert—Purchasing; and Gary—Sales. Richard Watkins and his older brother Redford designed the molds for the Watkins 23 using ideas from currently popular boats like the Venture 22 and 23. Some early W23’s had a wooden taffrail like the V23. In 1974 they began building a 23 foot sloop in a small rented building. Also in 1974 the OPEC oil embargo happened, gas prices skyrocketed and buyers began to turn from power boats to sail. It was an ideal time to be making sailboats! The W17 was introduced in 1975 with most of the boats sold going to a local club for one design racing. For the 1977 model year the W23 was upgraded to a full fiberglass interior and head liner and had “XL” added to the model designator.

Desiring to expand the line further upscale, the Watkins brothers commissioned Walter Scott a local naval architect to design the W27, Walter Scott also designed the Allmand 31 and other boats. (See Walter Scott Biography) Rich had met Mr. Scott while working for Ted Irwin. In 1977 the W27 was introduced and became an almost instant success, competing well with the likes of the Catalina 27 with better hardware and construction at a similar price. The boat would be the company's most popular model by a wide margin with 514 boats built. The W27 like the previous two models had a centerboard, however a fixed keel was optional and nearly all of the production was with the fixed keel. The addition of a third model required a larger building and the factory was moved to its final location around 1977. The building was preexisting but was modified and upgraded by adding a fire wall to provide a separate fiberglass shop and final assembly area.

Prior to the introduction of the W27, the Watkins Company produced less than 50 boats a year, but in 1978 with the first full model year of the W27 they were selling over 160 W27’s a year plus the other two models. Also the W27 sold for twice the $$ of the smaller boats. Business was booming but storm clouds were on the horizon, W27 volume dropped to around 100 boats for 1979. The since the early 60’s it had been a hay day for the boat building industry. It could be compared to Auto industry of the 1920’s or the computer/internet boom of the 80’s & 90’s. Anyone who was willing to quit his job at a big boat builder and start a small company could be rich and successful over night. One critic commented “You could sell all the leaky bathtubs you could make.” One huge problem loomed though. Fiberglass boats did not wear out like wood boats. In fact well cared for boats could last almost indefinitely and fiberglass boats had been built in high volume since the late 1950’s. Big successful boat companies like Columbia had begun to go bankrupt (1978). Interest rates had begun to rise to what would eventually be record levels making it expensive to borrow for a boat purchase. Looking at the looming storm clouds, the Watkins Brothers decided to sell the company. In August of 1979 the company was sold to an investor from Chicago, Illinois and the brothers exited the company. At the end of this phase of the company, Watkins Yachts had built nearly 600 total boats of the three models over a 6 year period. (See Richard Watkins Biography)

The Auroraglas Company was founded in 1978 by Al G. Larson and a silent partner for the purpose of building sailboats. The silent partner purchased the tooling for the Coronado 35 and several other hull molds from the now defunct Columbia Yachts where Al had worked previously. They modified the tooling for the Coronado 35 to become the A G Portman 36. The A G stands for Auroraglas. Around 19 boats were built by late 1979 or early 1980. Some of the modifications to the design include: changing the boat from a center cockpit to an aft cockpit, moving the windows from the hull to the deck house, creating a new outward flanging deck joint, creating a new deck house. For more information on the Coronado 35/Columbia 36: (See Columbia 36 PDF file)

The new owner of Watkins Yachts faced several problems, stiffer competition, an aging product line needing an update and lower volumes than had been previously experienced, Also with the exit of the Watkins Brothers, most of the management work force was gone. Watkins Yachts needed a new management team and new upscale products. The new owner and Al Larson some how became acquainted and in very late 1979 the Auroraglas Company and Watkins Yachts were commingled. Al Larson became the president of Watkins Yachts. The tooling for the A G Portman was moved to the Watkins factory, and Watkins Yachts began making and selling the A.G. Portman 36 as the Watkins W36 AC (Aft Cockpit). Al hired Dennis Robbins whom he had worked with at Endeavour Yachts to be the production manager and an experienced glass shop supervisor who Dennis had worked with at Irwin Yachts to manage the fiberglass mold department. Al handled much of the sales work as well as oversaw the design work. The new management team began to make changes almost immediately. The smaller boats (W17 and W23) were phased out quickly with as few as one W17 and four W23 boats built after the takeover. Quality and image became important. Al Larson even contemplated changing the name of the company to improve it’s image. The W36 became the flag ship of the line and the unique features of this boat design would be included in all future Watkins designs. Some of those features are: all opening ports (no dead lights), outward flanged deck-joint with aluminum thru bolted toe rail, sloping front cabin top with a large Bomar hatch, etc. See the “Construction” web page for a more detailed list, also see the W36 page. A salesman could point out all of the amenities on the smaller boats which were also on the W36. The new advertising tag lines were “big boat feel”, “cruise-ability”, “strong”, “and comfortable.

The first priority was upgrading the W27 as much a possible to fit the new image. The hull glass schedule was changed by adding more mat and woven roving and the keel/shoe was replaced with a monolithic keel. The W27 was originally designed as a stub keel with a centerboard. A shoal draft fixed keel version was also available by adding a shoe to the bottom of the keel and filling in the center board trunk. Only about 5 centerboards were ever built but the keel remained with the stub and add on foot. In 1981 the old keel was cut out of the mold and a new one piece keel was installed. Also the dead light windows were replaced with opening ports and the front hatch was changed from molded Plexiglas to a Bomar window hatch. Also a completely new interior was designed, including changing the saloon settees, new kitchen arrangement with angled sink etc and the MARK II or (MKII) designator was added to the model name.

In 1981 a modified version of the W27 became the W27P for pilot house. The boat began as a one off custom design for a customer and then Watkins decided to market it. Morgan and Pearson had come out with pilot house models so Watkins management felt they needed a model to compete. The original one off proto type was used to make a pop-off mold which was then used to make the rest of the boats. The mast was shortened and the boom raised to clear the cabin. A W27P owner claims that only 7 W27P’s were built and all of the 4 known to exist are 1981 models.

Also in 1981 a center cockpit version of the W36 was added to the line. This is ironic as the W36 started life as a Coronado 35 center cockpit modified by giving it a new deck/coach roof to become an aft cockpit. The original Columbia center cockpit design was very dated so a new from scratch deck & coach roof mold was designed. The hull and interior remained more or less the same as the W36 aft cockpit version.

In 1982 the W32 was introduced. Watkins Yachts had several old Columbia/Coronado hull molds that they had acquired with the assets of the Auroraglas. The W32 hull began life as a Columbia 32 but with considerable modifications it was transformed into the W32. Information about Columbia Yachts can be found at www.columbia-yachts.com. Changes included all opening ports, teak bulkheads and the Watkins aluminum deck flange/toe rail first used on the W36 and later used on the W25, W29-W30 and W33.

In mid 1982, the Al Larson’s silent partner in the Auroraglas Company sold out to Watkins Yachts. The Manufacturers Identification Code (MIC#) for the W36 hulls was then changed from “AJC” for Auroraglas Co. to “WYM” for Watkins Yacht and Marine ( this was the original name of the company under the Watkins brothers). Only about 8 or 9 W36’s were built after the change because of the introduction of the W32 which became the new flag ship and the older W36 model faded away. The last boat made in 1984 was the only hull made after 1982.

In 1983 the W25 was introduced. The W25 like the W36 and W32 began life as a Columbia hull, in this case a T-23. The in house Watkins design team modified it extensively to become the W25 including replacing the hat box deck joint with the Watkins external flanged deck joint, using the W32 aluminum toe rail, adding the Watkins signature forward sloping front cabin top with large Bowmar hatch and all opening ports. The rear transom was changed from reverse to vertical, a new keel form was added to the hull, the shear line was raised 6” and several inches were added to the fore and aft. The interior pan was designed from scratch and the deck/coach roof was completely new. Note: These models which came from modified Columbia/Coronado tooling were not cheap knockoffs of a high volume production boat. The boats design was substantially changed and the production was essentially hand built. I have looked at all of the original boats and it is difficult to see a resemblance in most cases. In the case of the W25, the modifications were so extensive, it is difficult to imagine any way the two hulls could have a similar linage. Not only the design was updated but the quality of the materials were upgraded. Teak replaced laminate and opening ports, replaced fixed, teak and holly soles replaced bare fiberglass, etc. (See Columbia T-23 pdf)

In 1984 the W27 was replaced by the W29. Through some in house design magic the W27’s raised deck was eliminated, the hull sides were raised and the boat was lengthened and widened to become the W29. The original W27 had a wide squat rectangular stern as the hull form was lengthened aft for the W29 the stern became narrower and raised out of the water for a more appealing look and less drag, almost the famous “Hour Glass” stern but with a shorter stem. The W27’s MK II interior was reused with almost no modifications.

Also in 1984 the W32 received a major upgrade. The hull was modified slightly by adding a reverse transom to become the W33. The Interior was upgraded to include more teak paneling and enclosed storage above the settees so it better resembled the original W36 flag ship of the line. At this point the W36 ceased production and the W33 became the largest boat in the model lineup.

In 1984 all of the ports on Watkins boats were changed from plastic frames to aluminum.

Around 1985, per a customer request, a deep draft version of the W25 was created by cutting the keel base out of the old Columbia mold and using it to make a plug for the current mold. A cast lead fin keel was then attached to the new smaller keel base. Only a few of these were made, somewhere between two and five. This keel and the standard W36 keel are the only external lead keels made by the Watkins Yacht and marine company. Around this time Dennis Robbins left the company to do consulting work for Island Packet and Irwin. For more information on Dennis Robbins see: http://www.endeavourowners.com/hist.html

In 1986 the Watkins Company was sold to the McLaughlin Body Co. (See McLaughlin Body) The company boat brochures now say next to the Watkins logo or Watkins Yachts address “A Division of McLaughlin”. Also two power boat models were added around 1986 to the line and called “SEAWOLF” models. The power boats were a 22 foot and a 26 foot off shore fishing boat. Both sizes came as either a center console or a walk around cuddy cabin. As part of the new marketing campaign the sailboats were also renamed “SEAWOLF” models. Sailboat brochures appeared with the "SEAWOLF" logo and wolf paw print. Some sailboats were shipped with the wolf paw graphic near the "Watkins" logo on the sides of the hull near the stern however the graphic was so un-seaman like that most owners removed it.

Sid Shackleford was hired as sales manager and he began to actively promote the SEAWOLF power boat line. He lined up several new dealers, mainly in Florida and a serious backorder developed. The problem was how to build 3 models of sailboats and 2 models of power boats in one small factory. Dennis Robbins was rehired in mid 1987 to improve production. Within six months the backorders evaporated as many of the initial power boat orders went to dealer inventory rather than sales to customers.

In mid 1987 Al Larson left the company to become sales manager at Tacoma Boat Works in Tacoma Washington. Tacoma was maker of custom yachts and commercial boats. Al was originally from the Canadian Pacific North West. Al has since retired to Florida.

Some of the factory photos at the end of this article show power boats being built in 1988. In the later years the power boats became the main focus of production, however Mr. McLaughlin required that the sailboat line be continued and wanted to keep it as viable as possible. Mr. McLaughlin was an avid sailor who owned a Morgan Outisland 41 which he kept near his second home in West Palm Beach, Fl and a Watkins 29 which he kept on the Mississippi river near his home in Moline, Illinois. A hand picked crew of six or seven people assembled all of the sailboats in the final years. During the last three years about two W25’s and one of either the W29 or the W33 were built each month.

In 1988 the W29 was modified by adding a reverse transom similar to the W33 to become the W30.

Gary Watkins had been a great salesman and in 1979 Watkins Yachts had over 20 dealers, but as the years passed Watkins Yachts kept slowly loosing dealers. During the final year of operation, they were down to only 3 dealers.

In October of 1989 the last known sailboat hull, W30 #90, was pulled from the mold as a 1990 model. All production stopped in November of 1989. Watkins did not go bankrupt, they simply shut down. Vital records and capital tools were sent back to the McLaughlin Body Co. and unwanted equipment was sold. After the company closed the current production molds and tooling were stored inside the plant until they were sold. Employees who stayed to the end were given generous severance pay.

The power boat line was sold to a company in Grand Cayman Islands about two years after the closure. The three sailboat models in production at time of closure were sold to a local man but he was unable to start up a business. The W25 molds eventually ended up in the hands of Compaq yachts who used the molds to create the Compac 25. The hull mold was left unchanged but Compac revamped the deck mold in the coach roof area and change the rectangular ports to round all to more closely match the appearance of the Compac brand. Compac also substituted Masonite and Formica for the teak doors and teak veneer bulkheads. The boat is still in production. The status of the other molds and tooling is unknown but presumed destroyed. Years after the business closed, several molds were seen lying in the weeds behind the plant by a Watkins owner visiting the area. These molds were the discontinued models: W17, W23, W27, W36 Eventually the buildings were sold to a plumbing supply, contractor.

Hull Numbering: Early Watkins 36C’s had hull numbers that begin with AJC standing for Auroraglas Company until July 1982. Afterwards the hull #’s begin with WYM standing for Watkins Yacht & Marine, Inc which was the original name of the Co prior to purchase by the McLaughlin Body Co. Watkins continued the serial #’s rather than starting over at zero when they changed the Manufacturers Identification Code (MIC) to WYM. Likewise the 36 center cockpit and 36 aft cockpit models share a common serial number sequence so that hull #36 might be a center cockpit and hull #37 might be an aft cockpit. Several other models used common serial #'s. The W27 and W27PH used one set of serial numbers. Also the W29/30 used a continuous serial number sequence as they converted over from making the older W29 to the newer W30 which is a W29 with a reverse transom; the serial number sequence was continued. The exception to the rule is the W32/W33. The hull numbers were restarted at #1 for the W33 model possible due to the extent of the redesign.

Page last updated 5/3/2008

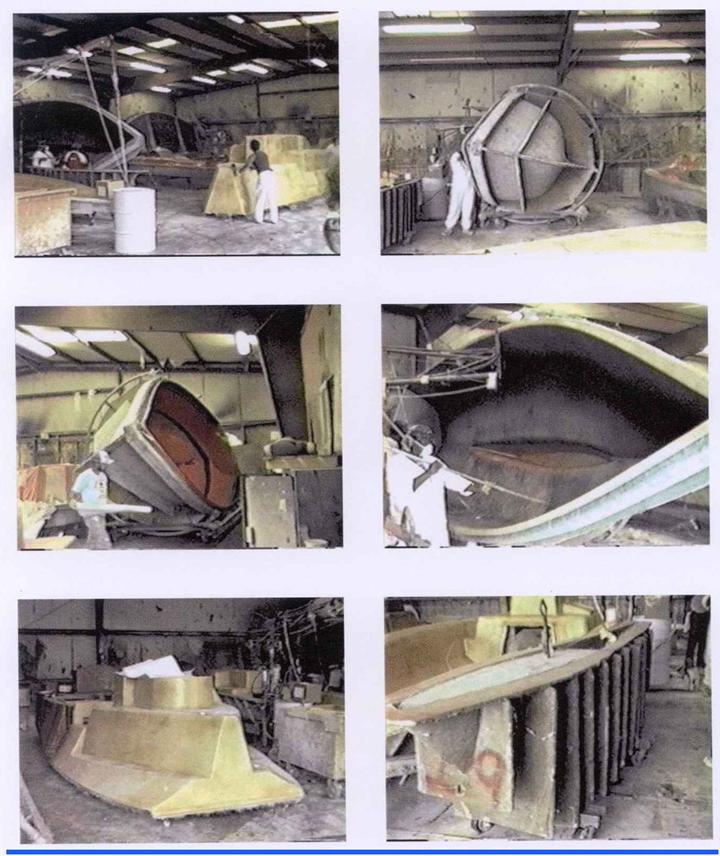

Below are factory interior and exterior photos taken in 1988.

Photo above is of a W30 being finished inside Watkins factory.

Photo above of factory interior. Boat on left is a Seawolf 22 ft. walk around.

Photo above of factory exterior. On left is Seawolf 22 ft. walk around, on the right is a W30.

In foreground of above photo is a keel mold for W30

used to mold the ballast. Note Lift eye sticking out of cement. Behind is

the W33 deck mold. Left Photo is of a 26 ft. power boat interior hull

liner. Left photo above is of a W30 hull mold. Right Photo

above is W25 hull being molded. On Left is W25 hull mold, right is W30 interior mold,

far right is W30 hull mold